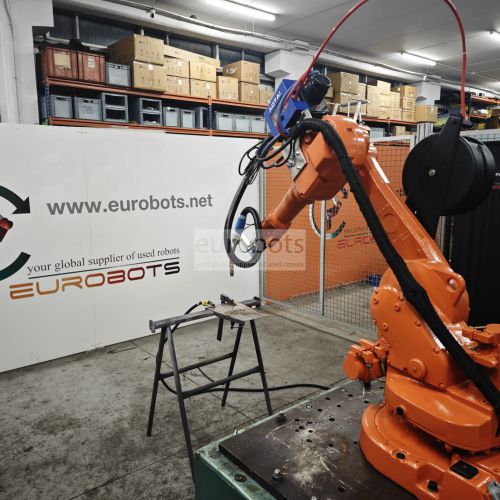

ABB IRB1600 with Aotai 500 amp welding machine

ABB welding system consisting of:

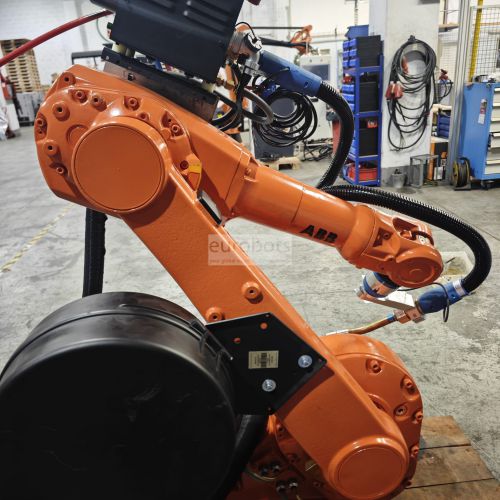

- 1 x ABB IRB1600 1450mm six axis industrial robot with IRC5 controller,

- 1 x Aotai AMIG 500PR Synergic Power source with 500A power, suitable for carbon steel and other alloys.

- Torch cleaning station ABICOR BINZEL

6 axis industrial robot suitable for machine tending, material handling, arc welding, cutting, dispensing, assembly, palletizing and packaging, measuring, die casting, injection moulding and handling of small parts of loads up to 10 kg and 1450 mm arm reach

Main advantages

The IRB 1600 has up to 50 percent shorter cycle times than competing robots in material handling, machine tending and process applications. It speeds up and slows down faster than other robots, saving time while moving between tasks. This is possible due to ABB’s patented second generation QuickMove motion control, combined with the robot’s strong motors and low friction losses in the spur gears

Low friction spur gears, and no unnecessary moves due to QuickMove and TrueMove, reduces power consumption down to 0.58 kW at max speed, and even less at low speeds. The airborne noise level of just <70 dB (A) secures a healthy sound environment.

- Maximum Load of Robot: 10 Kg

- Maximum Reach: 1450 mm

- Repeatability: 0.02 mm

- Controller: IRC5 M2004

Polígono Ugaldeguren III, nó 32, Pabellón 1

48170-Zamudio (Vizcaya) Spain

Tel. 0039 3387620171

0039 3395310971

daniela@eurobots.com

matteotenti@eurobots.com

Last updated: 2 Apr, 2025