ABB IRB 580

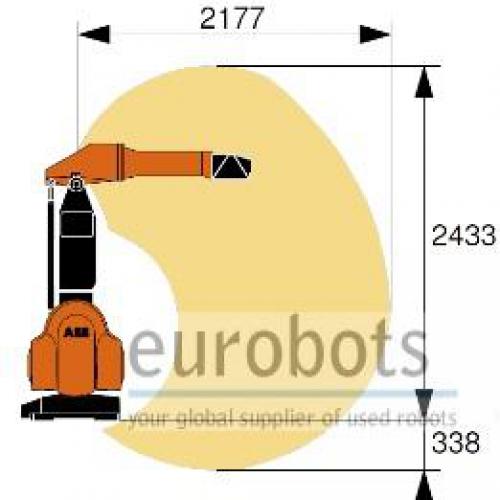

Year 2004. Only 8000 working hours. The IRB 580 combines the advanced functions of the IRB 5400 series with a compact design. The result is a highly flexible, cost-effective and accurate paint robot system.

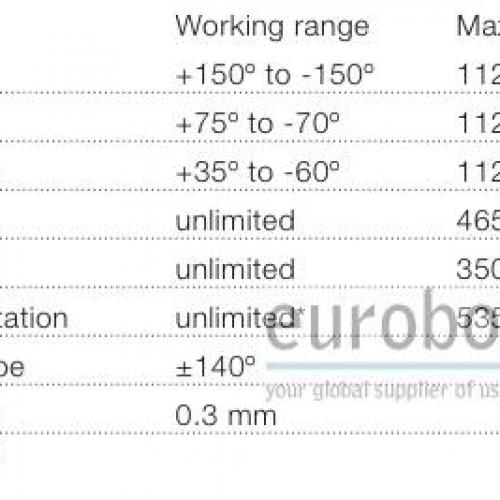

ABB’s high precision hollow wrist has a straight design that eliminates wear and tear on the paint- and air supply hoses, increasing the overall reliability. The wrist can rotate 140° in any direction. It makes IRB 580 one of the most versatile and easy to program paint robots in its class.

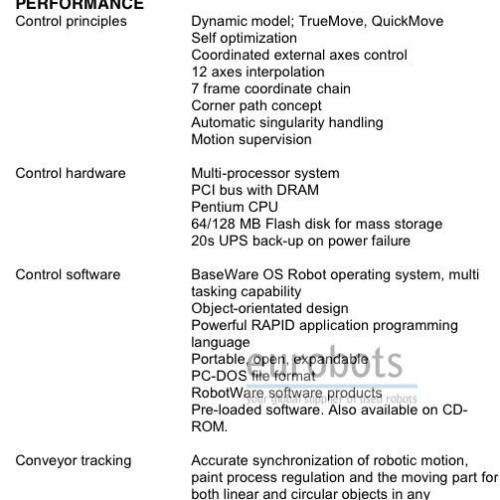

S4P+ controller

This controller for industrial paint robots comes with computing power and advanced paint process functions. The powerful S4P+ brings motion and process together, providing our systems with unrivalled overall performance.

The system software is delivered on a CD which also con- tains documentation, circuit diagrams and spare-part list. Software is installed from a PC using the easy to use Rob-Install program. The possibility to keep several software systems in parallel on the flash-disk makes software upgrades safe and fast. Two built-in Ethernet channels provide for easier service and factory networking.

The Paint process is handled by the powerful Integrated Process System (IPS). It features closed loop regulation, high speed and control for paint and airflow adjustment. The unique distributed time synchronized network will bring perfect timing to all process involved components.

ABB’s unique IPS ensures high finish quality and significant paint savings.

Polígono Ugaldeguren III, nó 32, Pabellón 1

48170-Zamudio (Vizcaya) Spain

Tel. 0039 3387620171

0039 3395310971

daniela@eurobots.com

matteotenti@eurobots.com

Last updated: 4 Apr, 2025