KUKA KR 180-2 PA

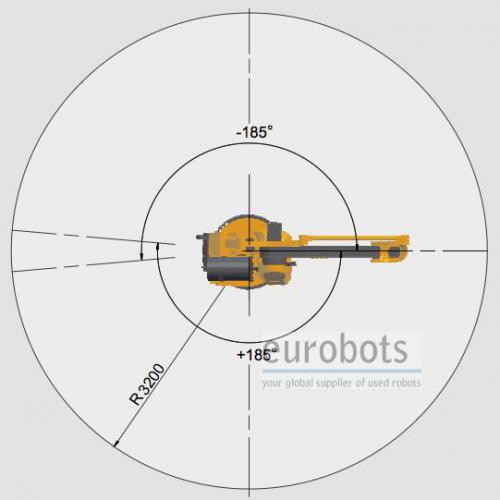

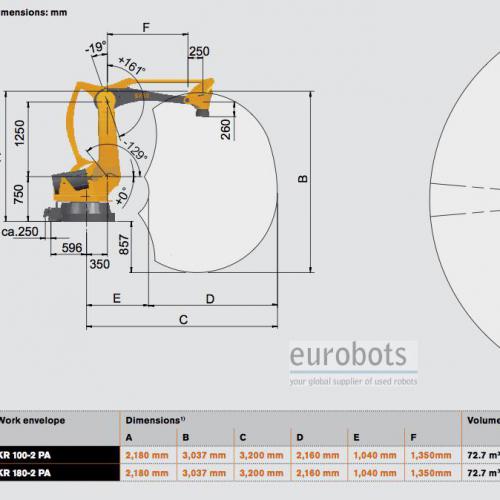

Second version of the popular 4 axis KR 180 PA-2, improved and enhanced. Design stays the same although motors and cabinets are of a newer generation. It is a special design robot used mainly for palletising featuring and fast speed in axis number one and four, which are critical in terms of cycle time for the palletizing process. An outstanding 3200 mm horizontal arm reach makes this robot the best option for your palletazing applications. Another typical use is plasma cutting or handling of 2D flat metal sheets. Another characteristic of this model is the carbon fiber upper arm which greatly enhances the stiffness of the whole unit.

Equipped with the KRC2 Ed05 controller.

KRC2 EDITION 2005 CONTROL FEATURES

The controller KR C2 edition2005 (ed05) is assembled in accordance with your individual requirements, using standard PC components and drive technology that has proved its worth in the field of automation. This guarantees you high reliability and continuous access to the benefits of cutting-edge technology.

For example, it is possible to integrate up to two external axes in the basic cabinet. In conjunction with a top-mounted cabinet, as many as six external axes can be controlled.

The controller stands out on account of its simple maintenance, good accessibility, modular structure and service-friendly design, which allows components to be exchanged quickly and easily. A wide range of diagnostic and troubleshooting functions, such as remote servicing via the Internet, together with numerous expansion options and a comprehensive safety concept round out the spectrum of services offered for the KR C2 edition2005, giving you everything you need to optimize your production.

Features and Advantages

- Uniform control concept for all KUKA robots – from low payloads right up to the heavy-duty category – means reliable planning and interchangeability

- “Plug and play” functionality enables rapid start-up

- Service-proven technology and standard PC components ensure maximum availability with minimum maintenance

- Modular design allows a wide range of customized hardware and software expansions

- Efficient interfaces and high compatibility due to PC-based technology

- Networked controllers that can communicate with each other in real time make it possible for a number of synchronized robots to work together on a single workpiece.

Caractéristiques principales

- Charge maximale du: 180 kg

- horizontale maximale bras Portée: 3200 mm

- Répétabilité: 0,25 mm

- Contrôleur: KR C2 ED05

Robot Speed Motion (RMS en º / seconde)

- Axe 1: 105º / s

- Axe 2: 105º / s

- Axe 3: 95º / s

- Axe 4: 300º / s

principales applications

- Manipulation

- Palettisation et l'empilage 2D horizontale générale

En attente de plus de stock

Industrial Machinery Export Bilbao, S.L.

Polígono Ugaldeguren III, nó 32, Pabellón 1

48170-Zamudio (Vizcaya) Spain

Tel. 0039 3387620171

0039 3395310971

daniela@eurobots.com

matteotenti@eurobots.com

Polígono Ugaldeguren III, nó 32, Pabellón 1

48170-Zamudio (Vizcaya) Spain

Tel. 0039 3387620171

0039 3395310971

daniela@eurobots.com

matteotenti@eurobots.com

Dernière mise à jour: 9 Apr, 2025