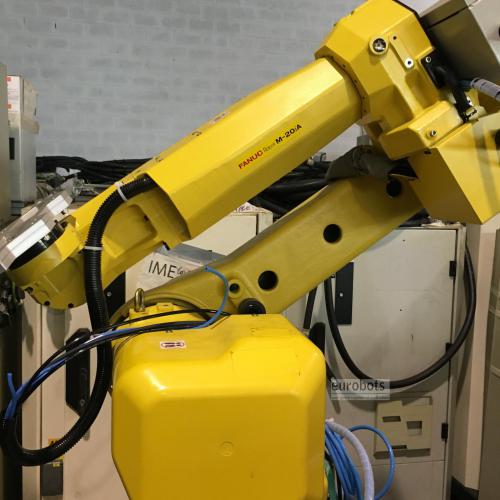

Фанук M-20iA

Innovative hollow upper arm and wrist low payload state of the art industrial robot. This new design prevents the classical wear out of the external pneumatic and signal electric connection of the gripper caused by continous physical contact causing tearing and rubbing in the task to be performed. As fot the rest, this 20 kg payload robot is almost identical in performance to the M16iB-20. The hollow arm and wrist together with the shelf greatly simpli es the integration engineers job.

To complement the built-in vision, the M-20iA has an integrated vision cable from the J1 base to J3 interface panel. This makes the addition of vision to the robot application much easier.

Coupled with the state of the art R-30iA controller.

R-30iA features

Robot general specifications

- Maximum Load of Robot: 20 Kg

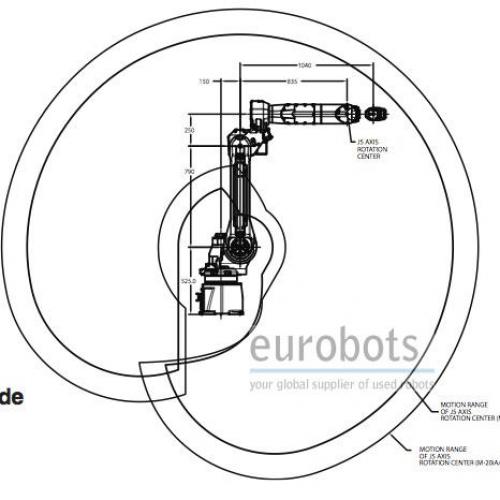

- Maximum Reach: 1811 mm

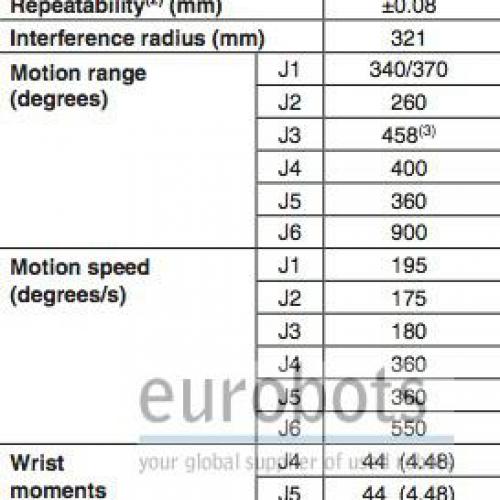

- Repeatability: 0.08 mm

- Controller: R-30iA

Robot Motion Speed

- Axis 1: 195º/s

- Axis 2: 175º/s

- Axis 3: 180º/s

- Axis 4: 360º/s

- Axis 5: 360º/s

- Axis 6: 550º/s

Motion range

- Axis 1: +-340/370º

- Axis 2: +-260º

- Axis 3: +-458º

- Axis 4: +-400º

- Axis 5: +-360º

- Axis 6: +-900º

Polígono Ugaldeguren III, nó 32, Pabellón 1

48170-Zamudio (Vizcaya) Spain

Tel. 0039 3387620171

0039 3395310971

daniela@eurobots.com

matteotenti@eurobots.com

Last updated: 5 Apr, 2025