ABB IRB1400 M2000 arc welding robot with IRBP 750K positioner and SKS or Kemppi

Year 2003/04, ABB genuine Flex arc welding, 9 axis cell consisting of:

- 1 x IRB1400 M2000 six axis robot with S4CPlus controller, 1,5 m arm reach and 5 kg payload.

- 1 x IRBP 750K welding positioner H shape (automatic load and unloading station)

- 1 x SKS or Keempi 400 amper

- 1 x automatic torch cleaning station

All components fully integrated and operational. Arc welding software included. All welding parameters controlled through the ABB teach pendant robot control system.

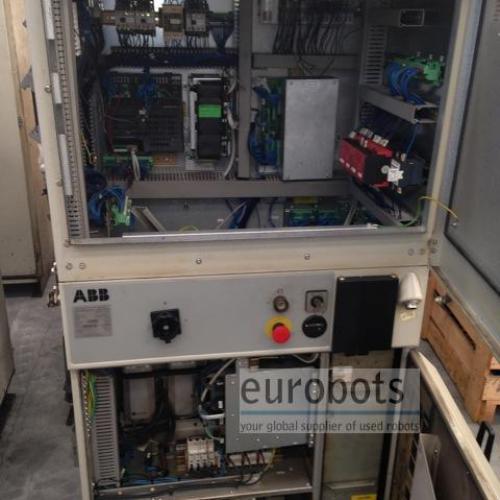

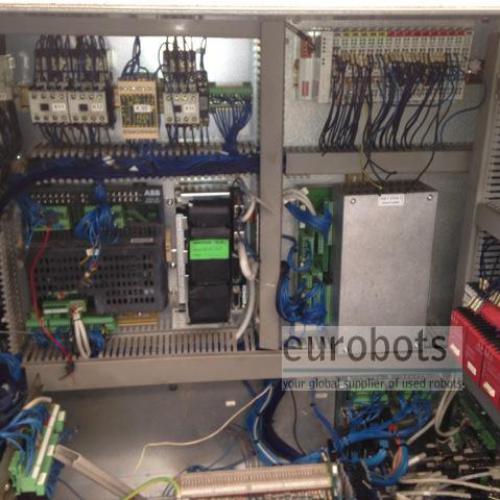

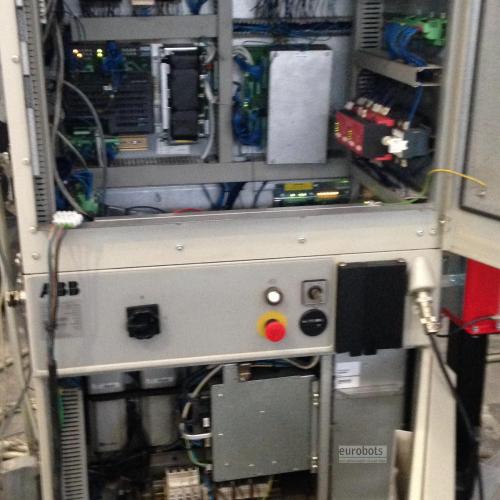

ABB S4CPlus controler features:

S4Cplus gives you superior motion control. It features dynamic model based control, QuickMove for short cycle times, and the TrueMove function for high precision path following ability independent of robot speed.

The S4Cplus system configuration capability and the powerful programming language RAPID make it easy to set up the controller for a wide range of applications.

Two built-in Ethernet channels provide easier service and factory networking.

There are field bus and serial channels for PLC and PC connections.

The controller supports TCP/IP, DNS and other protocols. A dedicated robot protocol, RAP, is available for control and monitoring.

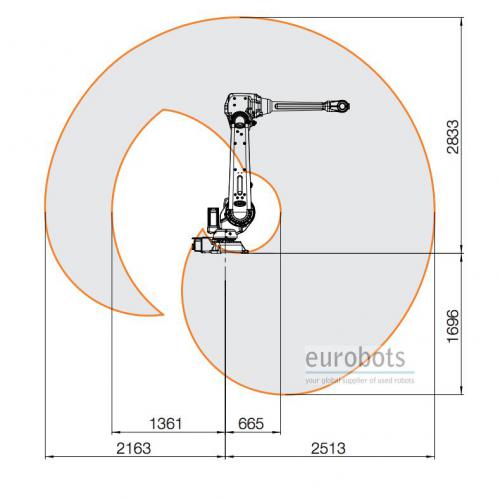

Robot Info :

- Maximum Load of Robot: 5Kg.

- Maximum Reach: 1440 mm.

- Repeatability: 0,05 mm.

- Controller: M2000 S4CPlus.

Robot Motion Speed :

- Axis 1: 120º/seg

- Axis 2: 120º/seg

- Axis 3: 120º/seg

- Axis 4: 280º/seg

- Axis 5: 280º/seg

- Axis 6: 280º/seg

Robot Applications :

- Arc welding

- Handling of small parts

- Process applications

Polígono Ugaldeguren III, nó 32, Pabellón 1

48170-Zamudio (Vizcaya) Spain

Tel. 0039 3387620171

0039 3395310971

daniela@eurobots.com

matteotenti@eurobots.com

Last updated: 2 Apr, 2025