ABB

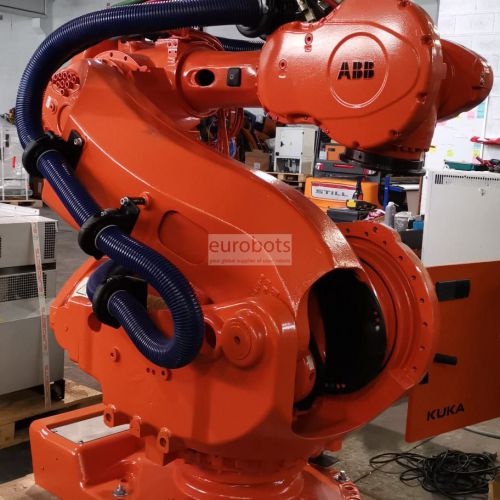

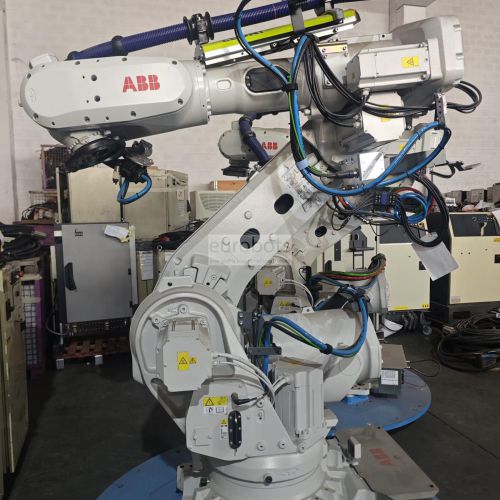

Explore our stock of new, used, second-hand, and refurbished ABB robots that we currently have in the inventory.

Our meticulous and all-encompassing procedure for refurbishing previously owned ABB robots guarantees their restoration to peak performance and dependability. This meticulous process involves several pivotal phases:

- Inspection and Evaluation: Thorough examination of each used robot to gauge its condition, identifying signs of wear, damage, or potential concerns. This initial evaluation serves as the foundation for the refurbishment strategy.

- Cleansing and Restoration: All constituents are meticulously cleansed, and any compromised parts are either repaired or replaced with authentic components. This covers not only visible elements but also internal facets like motors, sensors, and cables.

- Software Reset and Customization: The robot's software is reset to ensure seamless integration with technological options, and it is tailored to your specific requirements.

- Precision Calibration and Testing: The robot undergoes meticulous calibration to guarantee precise movements and positioning. Subsequently, it undergoes rigorous testing to gauge its performance across a spectrum of tasks and scenarios.

- Stringent Quality Control: A final quality assessment is conducted to verify that the refurbished robot adheres to our stringent benchmarks for performance, safety, and dependability.

- Optional Enhancements: Depending on the model and client preferences, we may provide optional upgrades like enhanced sensors, controllers, or software features to amplify the robot's capabilities.

- Packaging and Dispatch: Following successful completion of all refurbishment stages, the robot is thoughtfully packaged to safeguard against transit damage and dispatched to the designated customer location.

ABB is a leading brand in the market with cutting-edge robotics. This corporation of Swiss origin provides products and automation solutions that optimize industrial productivity and energy efficiency. Their equipment is easy to use and maintain. Operates in welding and handling sectors in general, ABB is constantly developing and improving automation processes for both the industrial and domestic sectors.

ABB Robots Controller abb cobots

ABB Robots Controller IRC5

ABB Robots Controller M2000 S4CPlus

THE FOLLOWING ROBOTS ARE NOT AVAILABLE AT THE MOMENT:

ABB Robots Controller abb cobots

ABB Robots Controller IRC5

Out of stock

Out of stock

ABB IRB1600 Flexarc M2004 IRC5 on track plus two IRBP 2000L positioners

Out of stock

Out of stock

ABB IRB1600 Flexarc M2004 IRC5 on track plus two IRBP 2000L positioners

Out of stock

Out of stock

IRB 2400 M2004 tandem two robots - 1 x IRC5 controller

Out of stock

Out of stock

IRB 6600 M2004 tandem 2 x robots controlled by one IRC5 cabinet

Out of stock

Out of stock

ABB IRB2400L Flexarc M2004 IRC5 with 2 x IRBP 250L positioners

ABB Robots Controller M2000 S4CPlus

Out of stock

Out of stock

ABB IRB1400 M2000 arc welding robot with IRBP 750K positioner and SKS or Kemppi

Out of stock

Out of stock

Welding robot ABB 2400L M2000 with 5 axis positioner IRBP250B and lineal track - 12 axis

ABB Robots Controller M97A-M98A-M99 S4C

ABB Robots Controller M94A-M96 S4

ABB Robots Controller M92-M93A S3

ABB Robots Controller S4P+ Paint

ABB Robots Controller IRC5P

Polígono Ugaldeguren III, nó 32, Pabellón 1

48170-Zamudio (Vizcaya) Spain

Tel. 0039 3387620171

0039 3395310971

daniela@eurobots.com

matteotenti@eurobots.com

Last updated: 22 Apr, 2025