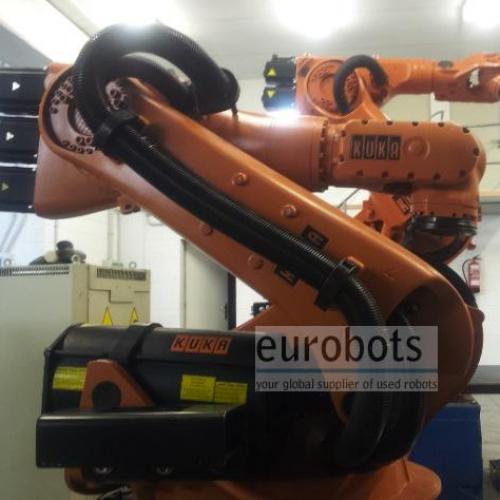

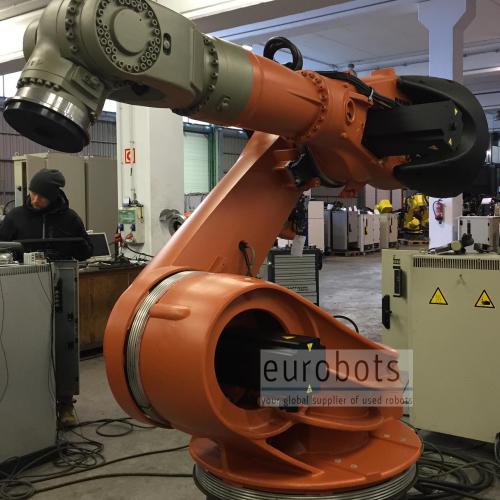

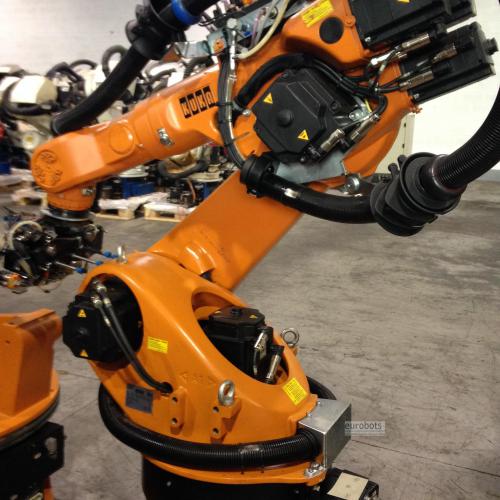

KUKA

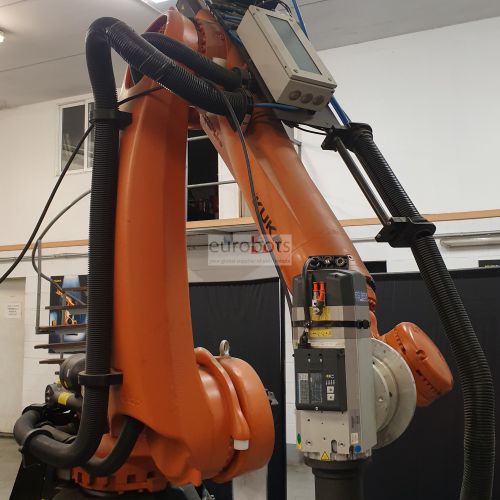

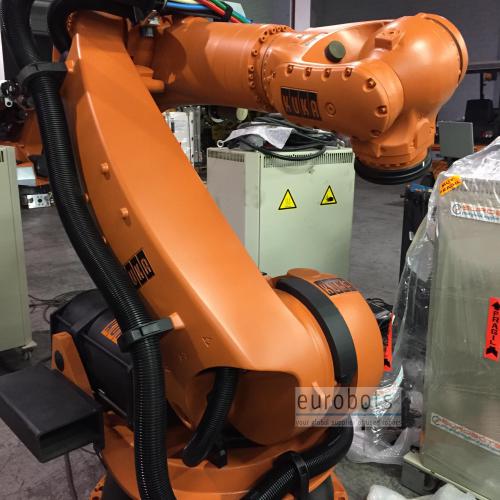

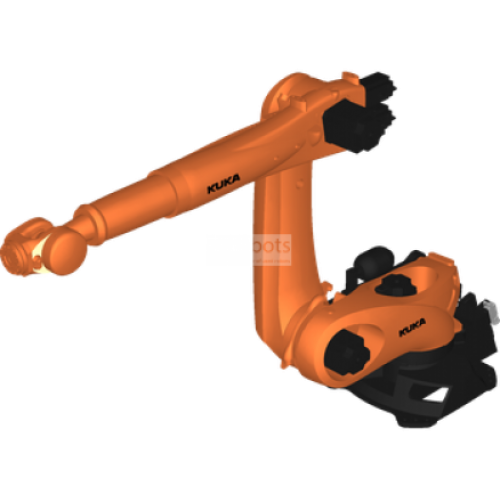

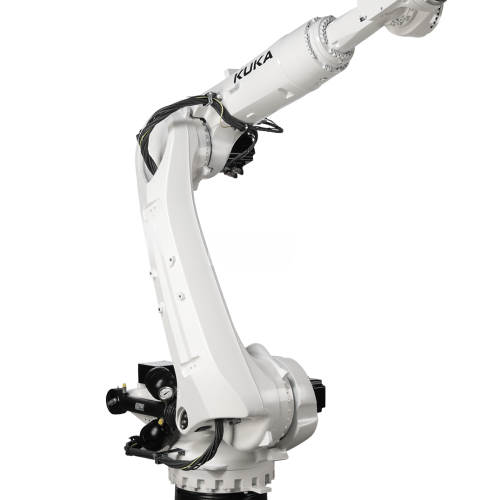

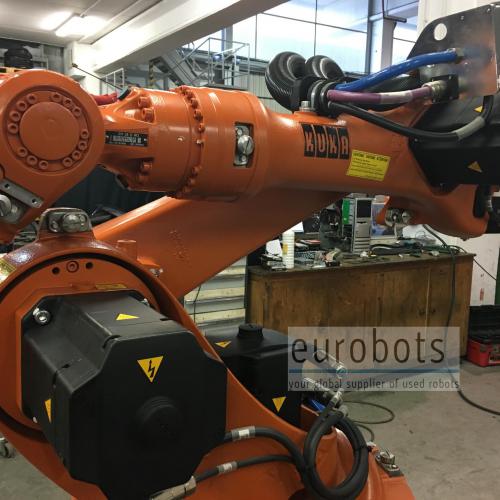

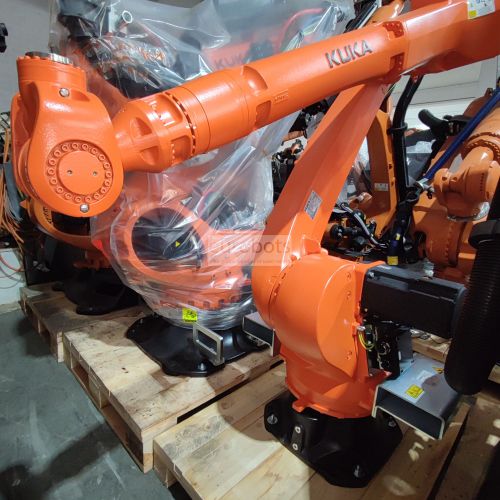

Discover our collection of new, used, second-hand, and refurbished KUKA robots that we currently have in stock.

Our refurbishing process for used KUKA robots is a meticulous and comprehensive procedure that ensures the robots are restored to their optimal performance and reliability. This process involves several key steps:

- Inspection and Assessment: Each used robot is thoroughly inspected to assess its condition, identifying any wear, damage, or potential issues. This initial assessment forms the basis for the refurbishment plan.

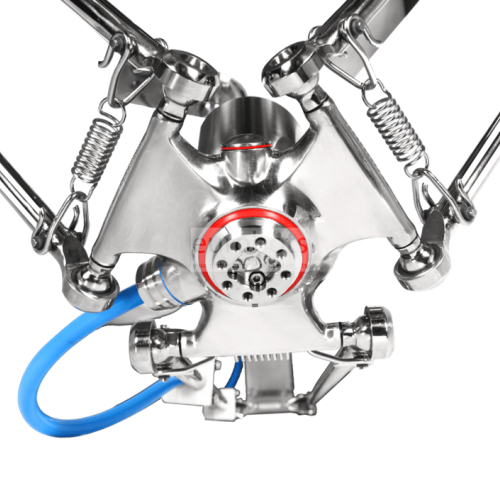

- Cleaning and Repair: All components are cleaned, and damaged parts are repaired or replaced with genuine components. This includes not only visible parts but also internal components like motors, sensors, and cables.

- Software factory reset and personalisation: The robot's software is reset to ensure compatibility with technology options and it is configured to your needs.

- Calibration and Testing: The robot undergoes meticulous calibration to ensure accurate movements and positioning. It is then subjected to rigorous testing to evaluate its performance across various tasks and scenarios.

- Quality Control: A final quality control assessment is performed to ensure that the refurbished robot meets our strict standards for performance, safety, and reliability.

- Optional Upgrades: Depending on the model and customer requirements, we may offer optional upgrades such as improved sensors, controllers, or software features to enhance the robot's capabilities.

- Packaging and Shipping: Once the robot successfully passes all stages of the refurbishment process, it is carefully packaged to prevent any damage during transit and shipped to the customer's location.

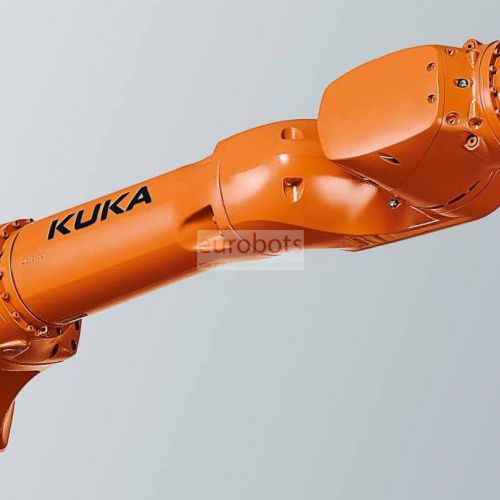

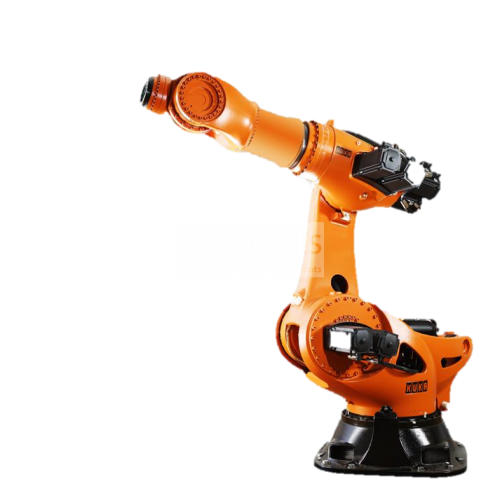

KUKA Roboter GmbH is a world leader in the manufacture of industrial robots and automation solutions for the main industrial sectors such as automotive, metallurgical, welding, food and plastics. Most KUKA robots are used by companies such as GM, Chrysler, Ford, Porsche, BMW, Audi, Mercedes-Benz, Volkswagen, Harley-Davidson, Boeing, Siemens, IKEA, Wal-Mart, Nestle, Budweiser, Coca-Cola and much others. We have a main plant with industrial robots, controllers, KUKA spare parts, etc. The KUKA group is an example of technological progress in both the industrial and medical divisions, proposing new automation procedures. It is a cost-effective solution for those who want to start automating manual processes.

KUKA Robots Controller KR C5

KUKA Robots Controller KR C4

Available

Available

KUKA KR22 with Fronius TPSi320 welding machine and 2 axis table

Available

Available

KUKA KR30-3 with 3 axis welding table, 500 amp Megmeet welding machine

Available

Available

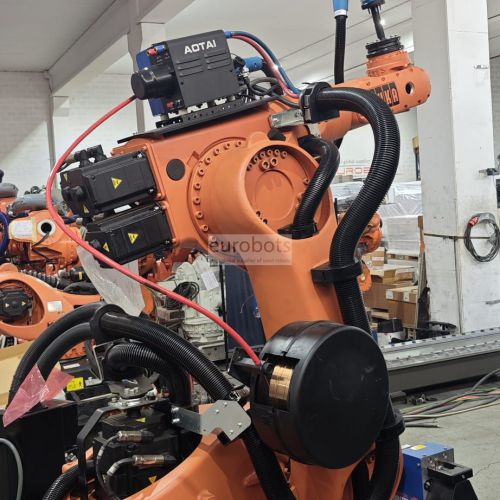

KUKA KR30-3 with 3 axis welding table, 500 amp Aotai welding machine

KUKA Robots Controller KRC2 Ed05

Available

Available

KUKA KR30/2 with H kuka positioner for welding cell

KUKA Robots Controller KR C2

Available

Available

Kuka KR15 nine axis arc welding robot with H shape positioner

Available

Available

Kuka KR30/2 nine axis arc welding robot with H kuka shape positioner

KUKA KR150 KRC2 with SKS power source and the big rotary table

THE FOLLOWING ROBOTS ARE NOT AVAILABLE AT THE MOMENT:

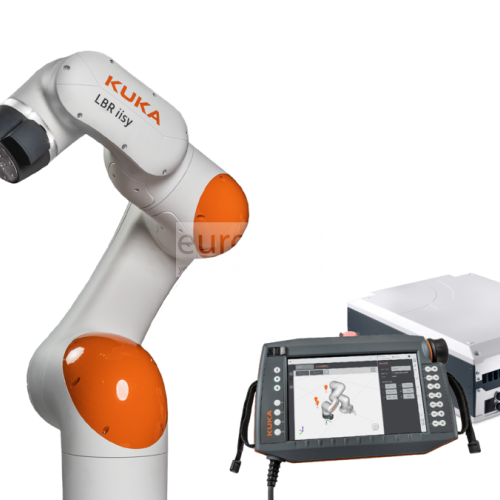

KUKA Robots Controller KUKA Sunrise

KUKA Robots Controller IISY cobot

KUKA Robots Controller KR C5

KUKA Robots Controller KR C4

KUKA Robots Controller KRC2 Ed05

Out of stock

Out of stock

Kuka KR 16 ten axis welding robot on track and H shape positioner

KUKA Robots Controller KR C2

Out of stock

Out of stock

KUKA KR30L krc2 with Fronius TPS4000 and H table (loading and unloading)

KUKA Robots Controller KR C1

KUKA Robots Controller KR C32

Polígono Ugaldeguren III, nó 32, Pabellón 1

48170-Zamudio (Vizcaya) Spain

Tel. 0039 3387620171

0039 3395310971

daniela@eurobots.com

matteotenti@eurobots.com

Last updated: 22 Apr, 2025